| Sign In | Join Free | My benadorassociates.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My benadorassociates.com |

|

Brand Name : HONGWANG

Model Number : SUS304

Certification : ISO 9001

Place of Origin : China

MOQ : 1 Ton

Price : 2100 - 3200 USD/Ton

Payment Terms : L/C, T/T, Western Union

Supply Ability : 20Ton per week

Delivery Time : 5 - 12 days based on the quantity

Packaging Details : standard packing for export

Products : Stainless Steel Sheet

Grade : SUS304

Thickness : 0.4 - 2.0mm

Tech : Titanium

Width : 1000mm 1219mm 1500mm or customs as request

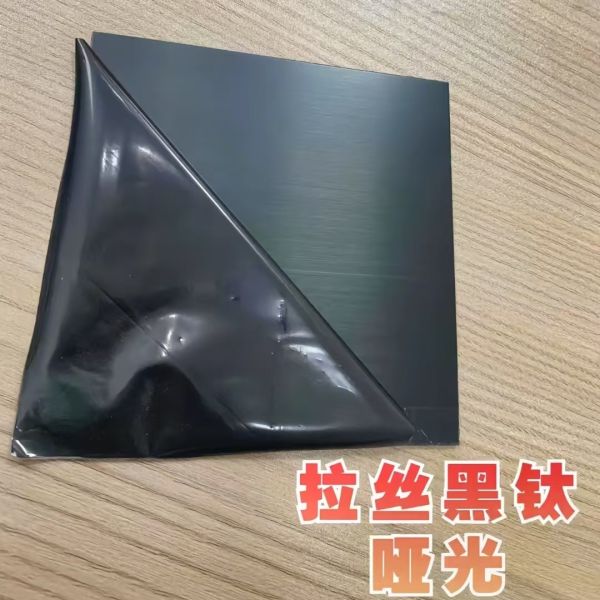

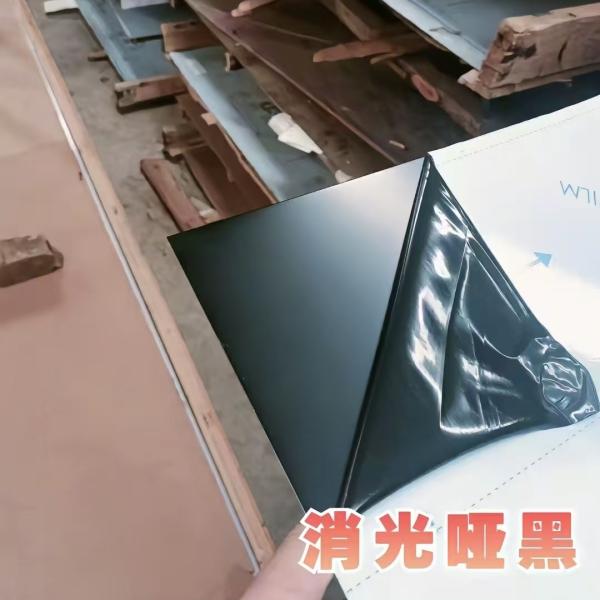

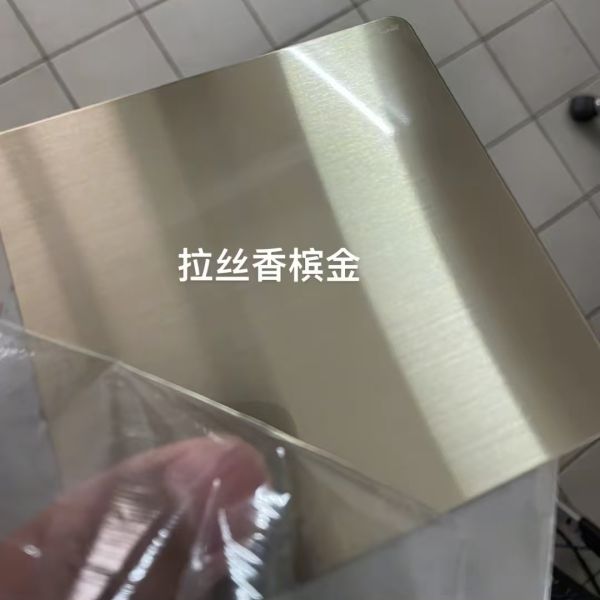

Surface : Black mirror, Gold Mirror , Hairline,etc

Standard : ASTM GB JIS EN DIN

MOQ : 1 Ton

Titanium Black Hairline Stainless Steel Sheet 304 / 1.4301 / SUS304 for Decoration

Products Specification

| Products Name | Colored Stainless Steel Sheet |

| Grade | SUS201 , SUS304 , SUS430 |

| Surface | 2B, BA , Mirror , NO.4 , Hairline , Gold Mirror , Gold Hairline , Bronze, Black, Blue , Gold Rose |

| Finish | Anti-Fringer Print and Laser Film |

| Width | 1000 1219mm 1500mm |

| Length | 1000-3000mm |

| Thickness | 0.40mm – 1.50mm |

| Region/Standard | Grade Designation | Key Note |

|---|---|---|

| United States (ASTM) | 304 | The most commonly referenced grade in North America |

| European Union (EN) | 1.4301 | Official designation under European standards, identical to 304 in composition |

| Japan (JIS) | SUS304 | Japanese industrial standard grade, widely used in Asian manufacturing |

| China (GB/T) | 06Cr19Ni10 | National standard equivalent, reflecting chemical composition (Cr: ~19%, Ni: ~10%) |

| Element | Content Range (%) | Function |

|---|---|---|

| Chromium (Cr) | 18.00 – 20.00 | The core element for corrosion resistance; forms a dense chromium oxide film on the surface to prevent rust |

| Nickel (Ni) | 8.00 – 10.50 | Enhances ductility, toughness, and resistance to acidic/alkaline environments; stabilizes the austenitic structure |

| Carbon (C) | ≤ 0.08 | Controls strength and weldability; low carbon content minimizes carbide precipitation (avoids intergranular corrosion) |

| Manganese (Mn) | ≤ 2.00 | Improves workability and hardenability without compromising corrosion resistance |

| Silicon (Si) | ≤ 1.00 | Aids in high-temperature stability and manufacturing (e.g., casting, rolling) |

| Phosphorus (P) | ≤ 0.045 | Reduces brittleness; kept at low levels to maintain material integrity |

| Sulfur (S) | ≤ 0.030 | Minimized to prevent corrosion and improve machinability |

| Property | Standard Test Method | Typical Value |

|---|---|---|

| Tensile Strength (σb) | ASTM A370 / EN 10002-1 | ≥ 515 MPa |

| Yield Strength (σ0.2) | ASTM A370 / EN 10002-1 | ≥ 205 MPa |

| Elongation at Break (δ) | ASTM A370 / EN 10002-1 | ≥ 40% (in 50mm gauge length) |

| Hardness (Brinell) | ASTM E10 / EN ISO 6506-1 | ≤ 201 HB |

| Hardness (Rockwell B) | ASTM E18 / EN ISO 6508-1 | ≤ 92 HRB |

| Impact Toughness (Charpy V-notch) | ASTM A370 / EN 10045-1 | ≥ 27 J (at 20°C, no brittle fracture) |

|

|

Titanium Black Hairline Stainless Steel Sheet 304 / 1.4301 / SUS304 for Decoration Images |